Smart Automation, Reliable Control

Endpoint was founded in 2019 in Loveland, Colorado with a primary focus on industrial control panel engineering and manufacturing. Since 2019 the company has focused on internal personnel growth and capability growth, with a strong focus on building partner relationships and bringing as much manufacturing in house as possible. Endpoint has expanded from industrial automation into the power distribution space, and most recently, Motor Control Centers (MCC’s). At Endpoint, we are always looking to the future to further expand capabilities and add expertise to our team in the ever-growing electrical manufacturing space.

Our industry partnerships include:

- Rockwell/Allen Bradley OEM Gold Partner

- ABB T-Max Link Partner

- Siemens Amplify Program Partner

- Eaton Ops Program Partner

Our UL Certifications include:

- UL 508A – Industrial Control Panels

- UL 698A – Industrial Control Panels interfacing with hazardous environments

- UL 891 – Switchboards

- UL 67 – Panelboards

- UL 50E – Type 3R enclosures

Endpoint houses a full engineering team of both mechanical and electrical engineers. The team’s deep experience in both industrial controls design and mechanical design allows us to engineer custom projects on abbreviated timelines. Endpoint’s engineers are well versed in ABB, Siemens and Eaton’s UL 891 and UL 67 designs.

Once a project is through the engineering process, the project then moves through manufacturing with Endpoint’s team of machine operators and machinists. Endpoint manufactures as much of a project in house as possible to better control lead times for our clients. Once a project has moved through manufacturing, it is assembled on the floor by our experienced electromechanical assembly team.

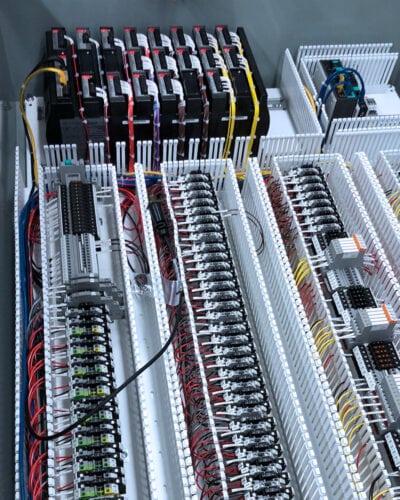

Endpoint’s panel shop is staffed by experienced panel builders that can handle everything from simple junction boxes to complex facility controls, to large high-volume projects. With its capable staff, Endpoint strives to be a trusted engineering and solutions partner for your critical projects.

The Minds Behind the Machines -

Meet the Team Powering Innovation.

Our Process: From Vision to Victory

At Endpoint Industrial Controls, we follow a streamlined, collaborative approach to projects to ensure both we and our customers are successful. We understand that projects can be complex. We are dedicated to understanding your specific needs and finding solutions that can meet or exceed expectations while fitting within your budget. Here’s how we do it.

Once a quote request is received, our quoting team works closely with the customer and our industry partners to provide a timely quote for your project with the best pricing and the fastest lead time possible. From there, our quoting team works to update the quote as necessary and ensure that all needs and goals of the project are met.

Upon receiving a purchase order and submittals are approved by the client; our engineering team takes over to fully design projects to meet specifications. Each project is custom designed to fit unique needs across a wide range of industries.

Once engineering is completed, the project moves into the manufacturing phase. All steel and copper components are manufactured in house with our machines, giving us the ability to cut down on lead times, as well as the ability to make changes to parts and pieces quickly if needed and ensure quality. As a project moves out of manufacturing, it moves to our assembly team’s hands where the project is built out and prepared for shipment and installation.